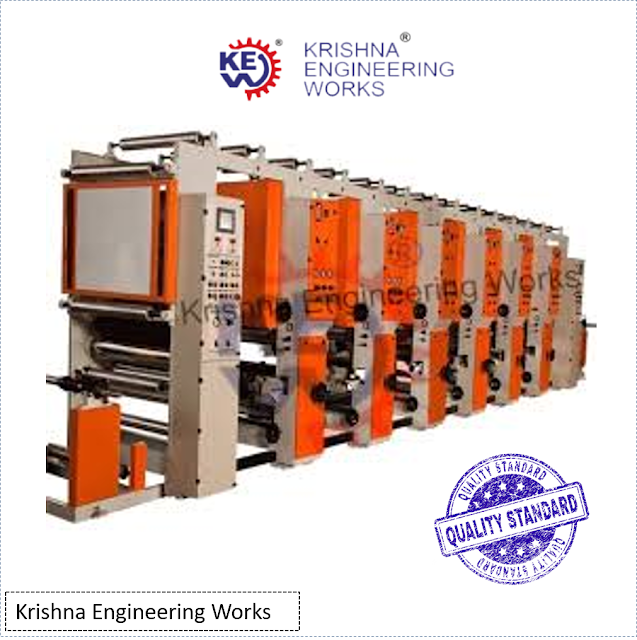

KNOWLEDGE OF ROTOGRAVURE PRINTING MACHINE

KrishnaEngineering Works is a company based in India that specializes in the manufacturing and exporting of a range of industrial equipment, including rotogravure printing machines. This company offers a variety of models of rotogravure printing machines, including standard and custom-designed machines to meet specific customer requirements. Some of the key features of rotogravure printing machines include:

High-precision engraving technology: We have used advanced engraving technology to ensure that the cylinders used in the printing machines are accurately engraved with the desired image.

Customizable configurations: Rotogravure offers customizable configurations for printing machines, allowing customers to choose the number of colors, printing width and other parameters to suit their needs.

Robust

construction: The printing machines manufactured by are made using

high-quality materials and are designed to withstand the rigors of heavy use in

industrial applications.

Advanced

control systems: rotogravure printing machines feature advanced control

systems that allow operators to precisely control the printing process and make

adjustments on-the-fly to ensure high-quality prints.

Easy

to use: Despite their advanced features, the printing machines manufactured are designed to be easy to use and maintain with user-friendly interfaces and simple maintenance procedures.

Overall, KEW is a reputable manufacturer of high-quality

rotogravure printing machines that are used by businesses around the world for

a variety of industrial applications.

What is the Rotogravure Printing Machine?

Rotogravure

printing is a type of intaglio printing process used for high-volume printing

of magazines, newspapers, packaging, and decorative prints. The process

involves etching the image onto a cylinder (made of copper or steel), which is

then coated with ink. The ink is then transferred onto the paper or other

substrate under pressure, creating a high-quality print with sharp, clear

images and rich, vibrant colors.

The

rotogravure printing machine consists of several key components, including a

series of cylinders, an ink system, a doctor blade, and a dryer. The printing

cylinders are engraved with the image to be printed, and the ink is applied to

the cylinders using an ink system. As the cylinder rotates, the doctor blade

removes any excess ink, leaving only the ink that is trapped in the engraved

cells. The paper or other substrate is then pressed against the cylinder, and

the ink is transferred onto the substrate.

This Machine is known for its high speed, consistent quality, and ability to print on a wide variety of substrates. It is commonly used for printing high-quality images on paper, plastic, and metal surfaces, and is particularly well-suited for printing large quantities of materials.

Rotogravure printing machine process

The

rotogravure printing machine process can be broken down into several steps:

Image

preparation: The first step in the process is to prepare the image that will be

printed. This may involve designing the image, creating a digital file, and

converting the file to a format that can be used by the printing machine.

Cylinder

preparation: The next step is to prepare the cylinder that will be used to

transfer the image onto the substrate. The cylinder is typically made of copper

or steel and is engraved with the image using a diamond-tipped stylus. The

depth and spacing of the engraved cells determine the amount of ink that will

be transferred onto the substrate.

Ink

preparation: The ink used in rotogravure printing is typically a solvent-based

or water-based ink that is formulated to adhere to the substrate and dry

quickly. The ink is mixed and then loaded into an ink system that will apply

the ink to the engraved cylinder.

Printing:

Once the cylinder is loaded with ink, the substrate (such as paper or plastic

film) is fed through the machine and pressed against the cylinder. The pressure

forces the ink out of the engraved cells and onto the substrate, creating a

high-quality print. The process is repeated for each color in the image, with

each color requiring a separate cylinder.

Drying:

After the ink is applied, the substrate is passed through a dryer to evaporate

any solvents or water and ensure that the ink adheres to the substrate.

Finishing: Depending on the application, the printed substrate may undergo additional processing steps such as laminating, cutting, or folding before it is ready for use.

Specifications of rotogravure printing

machines:

Web

Width: 20" to 80"

Number

of colors: 1 - 8 colors

Web

Roller: Aluminum Roller or Steel Roller

Web

roller: Steel rollers Aluminum rollers or

Machine

speed: Up to 250 m/min

Reel

diameter: 1000 mm

Cylinder

Dia: 100 mm to 800 mm

Unwind

shaft: Air shaft, tapper cone with solid shaft

Printing

material: aluminum foil, Film, Bopp, poly, paper, aluminum foil, pet,

polyester, metalized film, etc.

Infeed

unit: Synchronized control

Wed

Width: 500 mm to 2050 mm

Unwind/rewind

Reel Dia: 1000 mm

Film

Thickness: 6 Micron to 300 Micron

Paper

Thickness: 20 Gsm to 300 Gsm

Printing Unit:

Cylinder:

The cylinder is the heart of the printing unit. It is typically made of copper

or steel and is engraved with tiny cells that hold the ink. The depth and

spacing of the cells determine the amount of ink that will be transferred onto

the substrate.

Ink

system: The ink system is responsible for applying ink to the cylinder. It

typically consists of a series of rollers that distribute the ink evenly across

the cylinder's surface.

Doctor

blade: The doctor blade is a thin, flexible strip of metal that scrapes off any

excess ink from the cylinder's surface. This helps to ensure that only the ink

in the engraved cells is transferred onto the substrate.

Substrate

feed: The substrate feed is the mechanism that moves the substrate (such as

paper or plastic film) through the printing machine. It is typically a series

of rollers that apply pressure to the substrate, pressing it against the

cylinder and transferring the ink.

Dryer:

The dryer is used to evaporate any solvents or water from the ink and substrate

after printing. This helps to ensure that the ink adheres to the substrate and

does not smudge or smear.

Control system: The control system is the brain of the printing unit. It manages all the components and ensures that the printing process is carried out accurately and efficiently.

In

conclusion, a rotogravure printing is a specialized industrial machine

that uses engraved cylinders to transfer ink onto a substrate, typically for

printing images or designs. The printing process is highly accurate and capable

of producing high-quality prints at high speeds and volumes. The machines are

used in a variety of industries, including packaging, label printing, and

publishing. For more information visit our website: www.krishnaengineeringworks.com or email: kewinquiry@gmail.com.

Comments

Post a Comment